Van Doleweerd thinks that the use of 3D printers in restaurants can mainly contribute to the experience for guests and create awareness around food waste. Some restaurants even place their printer at the table, so that guests can witness with their own eyes, how their food is printed. I hear you thinking but won’t a 3D printer take over the role of the chef? "Certainly not!" says Van Doleweerd. “The 3D printer is a tool. It provides extra opportunities for a chef to be creative with ingredients. It also contributes to the experience in a restaurant. This year we've gotten used to "dining out, at home". As soon as the restaurants are allowed to run in full capacity again, food printing can add value to the experience that a restaurant offers.”

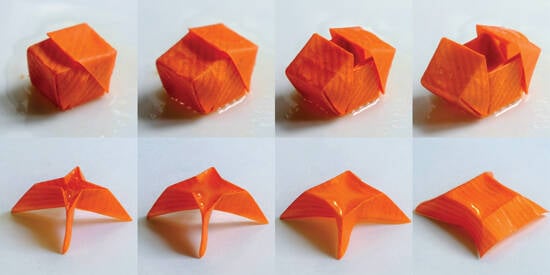

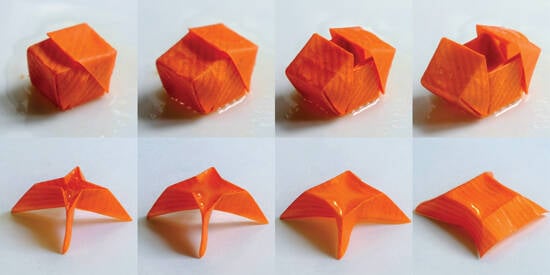

Van Doleweerd is well aware that the experience of food is becoming increasingly important. That’s why she’s developing new innovations around food. Her new project is researching shape-changing food. Dishes that take on a new guise, when you add a sauce, for example. Despite the fact that an experience has a growing function, Van Doleweerd's main focus remains on combating food waste. “In addition to experimenting with shape-changing food, we are currently also looking at how we can use 3D printing to combat food waste on a large scale. Chefs set an example, but we would love to work with large companies.”

Van Doleweerd no longer experiments with simple piping bags. She can now make the most special creations with a 3D printer. Upprinting Food mainly works with restaurants in the higher segment. Upprinting Food helps chefs come up with new innovative designs every month. “We change with the menu and use residual flows that are available at that time. Together we make a special product every time,” says Van Doleweerd. “An example is the crispy fish skin we created with restaurant ADAM, in Amsterdam. We printed the fish skin in the shape of a fishbone. It was then dried and baked. This way, the restaurant could use their waste as an edible and pretty addition to a meal.”

The food-tech company doesn’t just help chefs design new products, but also teaches them how to use the printer. Van Doleweerd: “We help with the installation of the printer, give workshops about the possibilities and make sure that chefs feel comfortable using it themselves. Often people expect it to be a very complex process. But you can make it as easy or difficult as you want. A simple logo is done in no time, and takes the printer about one or two minutes. If you want a larger design, it will take a little longer.” Not all residual flows are equally easy to process, according to Van Doleweerd, but it often succeeds with the right recipe. For example, together with Instock, a restaurant in Amsterdam with the aim to combat food waste, the company made an edible container from the green leaves of the leek. Leek is one of the most difficult residual flows to process, because it’s so rich in fiber. Van Doleweerd: "By making a puree in combination with breadcrumbs, we were able to print a nice shape with it."

Until now Natural Machines focuses mainly on users in professional kitchens. Kuczma: “These are obviously restaurants and food producers, but also parties in the healthcare sector.” The possibilities with a 3D printer for making new products are, according to Kuczma, enormous and have many advantages; ingredients that have a positive effect on health can be easily added to meals and harmful preservatives can be eliminated. Kuczma also explains that 3D printing can contribute to food waste by turning residual flows into beautiful new products. In addition, the 3D printer can be used to create special decorations, logos and personalized shapes. The company has international partnerships to their name with major hotel groups, universities, food producers and healthcare institutions.

But before 3D food printers truly become mainstream, a lot of technical progress is still needed. Today's printers are especially suitable for products that still have to be baked. The printers cannot heat or cook products yet. Kuczma: “Before I was involved with 3D printers I was in the mobile phone business. I often compare the 3D food printers on the market with the very first smartphone. Much remains to be done to optimize processes and use. In the future, we hope to heat up products and even yarn with precision lasers in the printers.”

The company The Natural Machines in Barcelona, is a pioneer in building 3D printers for food. Founder Lynette Kuczma started developing 3D food printers when a friend who owned a vegan bakery ran into trouble. Said friend had plans to expand her business, but incurred high costs for logistics. The solution according to Kuczma? A hyper local production facility, aka a food printer.

After years of development, the Foodini - the name of the printer - is available to anyone who’s interested. The printer works as follows. In special capsules, the user adds pre-cooked food, which is then squeezed out through a mouthpiece. A control system moves the capsule in a very precise way to create any chosen design. It creates shapes that are stacked layer upon layer to create three-dimensional creations. In addition to the printer itself, Natural Machines also develops software for food design. In the "library" shapes to start designs and recipes can be found, but users can also create their own design with a special app on a tablet or smartphone.

“In the world of food there’s a lot of waste and residual flows. I wanted to find a solution to still process leftovers and "unusable" food into beautiful products. 3D printing seemed like a suitable technique for this,” says van Doleweerd. Initially, the young entrepreneur didn’t have a 3D printer at her disposal. To test whether her recipes had the right structure and could be sprayed in a nice shape, she experimented with pastry bags. “If you look at it very simply, a 3D printer also just presses a puree through a syringe. I thought if it goes well with an ordinary piping bag, then it should also work with a 3D printer.

Van Doleweerd studied industrial design at the Technical University in Eindhoven in the Netherlands. At her university, students already made a lot of use of three-dimensional printing. It’s a common tool used by designers to make prototypes. However, 3D-printing food was still a relatively unknown territory at the time. Van Doleweerd, who, in addition to her studies, had a big interest in high-quality cooking, decided after a minor in food technology to study food printing. There are now many companies that are engaged in food printing, but Upprinting Food distinguishes itself from the rest because the company wants to prevent food waste by using technology.

Elzelinde van Doleweerd

A cake with a personalized logo, which is printed live while the guest waits. It sounds ultramodern, but in 2021 we’ve arrived in the future. Printing food isn’t just a fun gimmick, the technology can also be used to combat food waste.

Lisa Appels Upprinting Food Xiao Er Kong

3D printing in restaurants helps to reduce food waste

Foodprinting company Upprinting Food uses scraps - such as stale bread and vegetable skins - to create new products. Co-founder Elzelinde van Doleweerd talks about how food printing can contribute to the reduction of food waste.

expert opinion

6 min

one printed meal for table three please!

Van Doleweerd thinks that the use of 3D printers in restaurants can mainly contribute to the experience for guests and create awareness around food waste. Some restaurants even place their printer at the table, so that guests can witness with their own eyes, how their food is printed. I hear you thinking but won’t a 3D printer take over the role of the chef? "Certainly not!" says Van Doleweerd. “The 3D printer is a tool. It provides extra opportunities for a chef to be creative with ingredients. It also contributes to the experience in a restaurant. This year we've gotten used to "dining out, at home". As soon as the restaurants are allowed to run in full capacity again, food printing can add value to the experience that a restaurant offers.”

Van Doleweerd is well aware that the experience of food is becoming increasingly important. That’s why she’s developing new innovations around food. Her new project is researching shape-changing food. Dishes that take on a new guise, when you add a sauce, for example. Despite the fact that an experience has a growing function, Van Doleweerd's main focus remains on combating food waste. “In addition to experimenting with shape-changing food, we are currently also looking at how we can use 3D printing to combat food waste on a large scale. Chefs set an example, but we would love to work with large companies.”

Van Doleweerd no longer experiments with simple piping bags. She can now make the most special creations with a 3D printer. Upprinting Food mainly works with restaurants in the higher segment. Upprinting Food helps chefs come up with new innovative designs every month. “We change with the menu and use residual flows that are available at that time. Together we make a special product every time,” says Van Doleweerd. “An example is the crispy fish skin we created with restaurant ADAM, in Amsterdam. We printed the fish skin in the shape of a fishbone. It was then dried and baked. This way, the restaurant could use their waste as an edible and pretty addition to a meal.”

The food-tech company doesn’t just help chefs design new products, but also teaches them how to use the printer. Van Doleweerd: “We help with the installation of the printer, give workshops about the possibilities and make sure that chefs feel comfortable using it themselves. Often people expect it to be a very complex process. But you can make it as easy or difficult as you want. A simple logo is done in no time, and takes the printer about one or two minutes. If you want a larger design, it will take a little longer.” Not all residual flows are equally easy to process, according to Van Doleweerd, but it often succeeds with the right recipe. For example, together with Instock, a restaurant in Amsterdam with the aim to combat food waste, the company made an edible container from the green leaves of the leek. Leek is one of the most difficult residual flows to process, because it’s so rich in fiber. Van Doleweerd: "By making a puree in combination with breadcrumbs, we were able to print a nice shape with it."

Until now Natural Machines focuses mainly on users in professional kitchens. Kuczma: “These are obviously restaurants and food producers, but also parties in the healthcare sector.” The possibilities with a 3D printer for making new products are, according to Kuczma, enormous and have many advantages; ingredients that have a positive effect on health can be easily added to meals and harmful preservatives can be eliminated. Kuczma also explains that 3D printing can contribute to food waste by turning residual flows into beautiful new products. In addition, the 3D printer can be used to create special decorations, logos and personalized shapes. The company has international partnerships to their name with major hotel groups, universities, food producers and healthcare institutions.

But before 3D food printers truly become mainstream, a lot of technical progress is still needed. Today's printers are especially suitable for products that still have to be baked. The printers cannot heat or cook products yet. Kuczma: “Before I was involved with 3D printers I was in the mobile phone business. I often compare the 3D food printers on the market with the very first smartphone. Much remains to be done to optimize processes and use. In the future, we hope to heat up products and even yarn with precision lasers in the printers.”

The company The Natural Machines in Barcelona, is a pioneer in building 3D printers for food. Founder Lynette Kuczma started developing 3D food printers when a friend who owned a vegan bakery ran into trouble. Said friend had plans to expand her business, but incurred high costs for logistics. The solution according to Kuczma? A hyper local production facility, aka a food printer.

After years of development, the Foodini - the name of the printer - is available to anyone who’s interested. The printer works as follows. In special capsules, the user adds pre-cooked food, which is then squeezed out through a mouthpiece. A control system moves the capsule in a very precise way to create any chosen design. It creates shapes that are stacked layer upon layer to create three-dimensional creations. In addition to the printer itself, Natural Machines also develops software for food design. In the "library" shapes to start designs and recipes can be found, but users can also create their own design with a special app on a tablet or smartphone.

“In the world of food there’s a lot of waste and residual flows. I wanted to find a solution to still process leftovers and "unusable" food into beautiful products. 3D printing seemed like a suitable technique for this,” says van Doleweerd. Initially, the young entrepreneur didn’t have a 3D printer at her disposal. To test whether her recipes had the right structure and could be sprayed in a nice shape, she experimented with pastry bags. “If you look at it very simply, a 3D printer also just presses a puree through a syringe. I thought if it goes well with an ordinary piping bag, then it should also work with a 3D printer.

Van Doleweerd studied industrial design at the Technical University in Eindhoven in the Netherlands. At her university, students already made a lot of use of three-dimensional printing. It’s a common tool used by designers to make prototypes. However, 3D-printing food was still a relatively unknown territory at the time. Van Doleweerd, who, in addition to her studies, had a big interest in high-quality cooking, decided after a minor in food technology to study food printing. There are now many companies that are engaged in food printing, but Upprinting Food distinguishes itself from the rest because the company wants to prevent food waste by using technology.

Elzelinde van Doleweerd

Foodprinting company Upprinting Food uses scraps - such as stale bread and vegetable skins - to create new products. Co-founder Elzelinde van Doleweerd talks about how food printing can contribute to the reduction of food waste.

A cake with a personalized logo, which is printed live while the guest waits. It sounds ultramodern, but in 2021 we’ve arrived in the future. Printing food isn’t just a fun gimmick, the technology can also be used to combat food waste.

Lisa Appels Upprinting Food Xiao Er Kong

3D printing in restaurants helps to reduce food waste

6 min